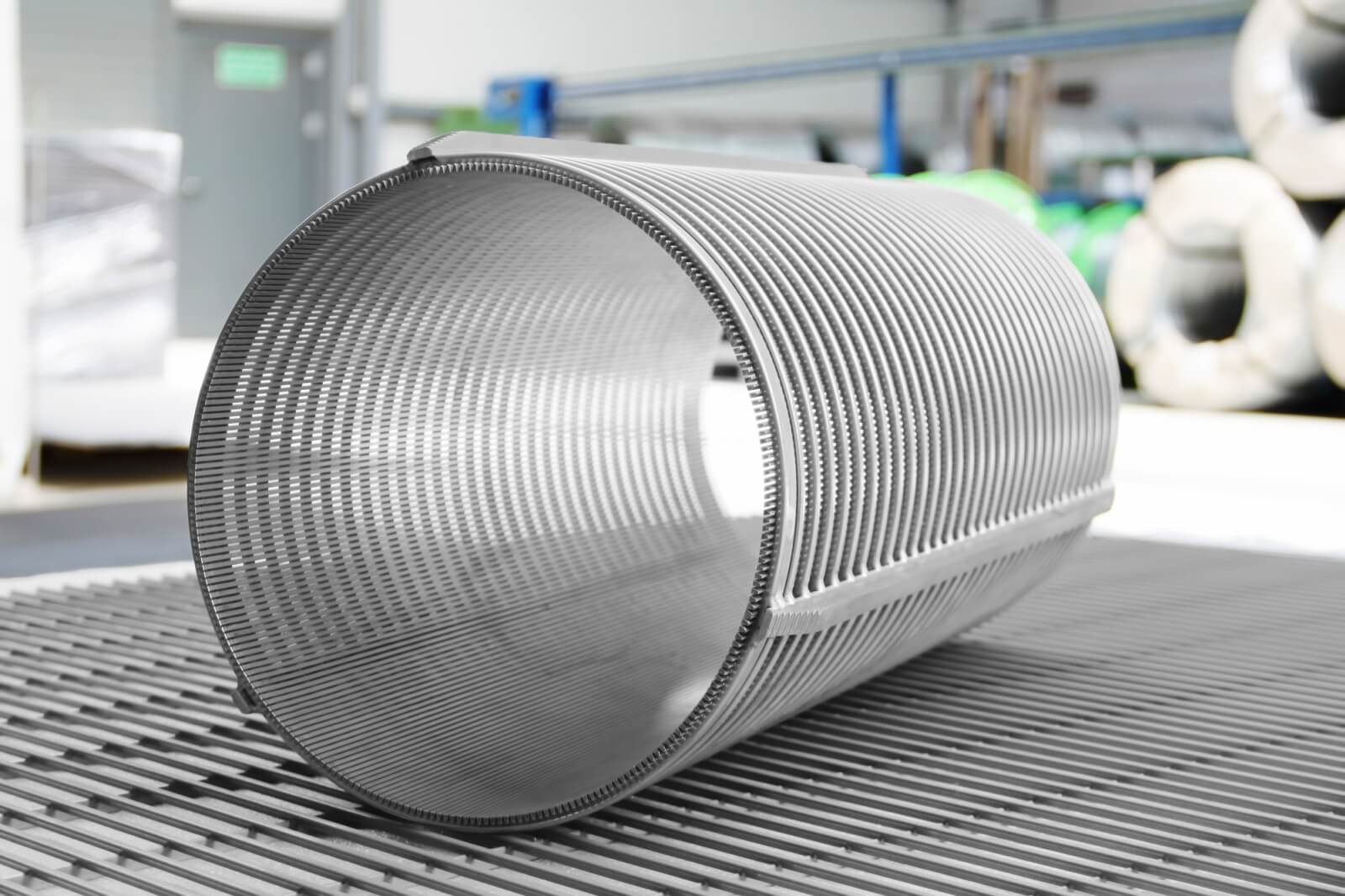

Wedge wire is used for separation, dehydration, screening, and filtration applications. Many industries make use of these V-shaped wires that include agriculture, mining, oil refining, pharmaceuticals, food, and beverage.

Manufacturers take care of the manufacturing process very precisely on all kinds of projects. The V-shaped products are made with specifications based on the application requirement of the industry standards.

Premium Wedge Wires for Specified Requirements

Numerous industries rely on wedge wire because of its versatile nature to be used for multiple applications. Most industries ask for stainless steel for the product specifications for long-lasting usage. These can be for just mere filtration screens to the large architectural panels.

The stainless-steel wedge wires are manufactured by grating using high-precision tools that provide high-performance results. They have high tolerances for ensuring efficient filtration for any kind of project. The standard wire will be able to handle the high pressures to take up the heavy loads to match up to the industrial provisions.

The wedge wires are made up of stainless steel to make sure the product has corrosion-resistant. It allows to last for longer periods by maintaining the filtration accuracy even though after using again and again.

Prominent Applications of Wedge Wire

There are several applications that make it a prominent product for many industries.

Food and Beverage: In these industries, the food and drinks need to be filtered to purify the composition and impurities. When there is the production of soups, teas, cold-pressed juices, alcohol, and chocolate a wedge wire is sure to be used for perfect filtration. The stainless steel has sterility that ensures the quality of food and beverages while making them safe for consuming.

Oil and Coal: Mining, solid filtration, and purification are mandatory when you are dealing with the mining and coal industries. The wedge wire filters the oil by separating the solids from it. As it known fact that these materials are resistant materials and the compatibility of handling heavy loads is the add-on point for choosing wedge wire.

Pharmaceutical: This industry needs a high-level purification process for making them safe for consumption. Medications and drugs need complete care during manufacturing, as one mistake can cost so much to the industries. And these wedge wires must be reliable to filter the powders like materials too.

Agriculture: Having natural fertilizers can make a huge difference in agricultural procedures. The wedge wires are used for separating the animal feed and fertilizer manures before distribution. The V-shaped profiles are majorly used because of their self-cleaning and anti-clogging applications for operation efficiency.

How do Manufacturers deal with Wedge Wire Manufacturing Procedures?

The wedge wire is manufactured from stainless steel and allows them the reliable performance that makes it the best one for the various industries. They have experience in dealing with different types of wedge wire products to provide for various clients. The resources, tools, and the talent of working procedure produce the major product output. As per the situation and demand they maintain the timeline to meet y to the requirements of the clients. The developing team and the engineering teams collaborate for bringing the best out of all.

The way we consume entertainment has changed dramatically, with Subscription Video on Demand (SVOD) leading…

The Evolution of Inventory Tracking RFID inventory management software is transforming how businesses track, manage,…

The Unexpected Costs of Unprotected Windshields Polaris Ranger windshields protection is more than just a…

Probably one of the best things people do to secure their finances is the purchase…

The iPhone 15 is still a great buy Released in 2023, the iPhone 15 brought…

By Josh Breaker-Rolfe Data security posture management (DSPM) is the rising star of the data…