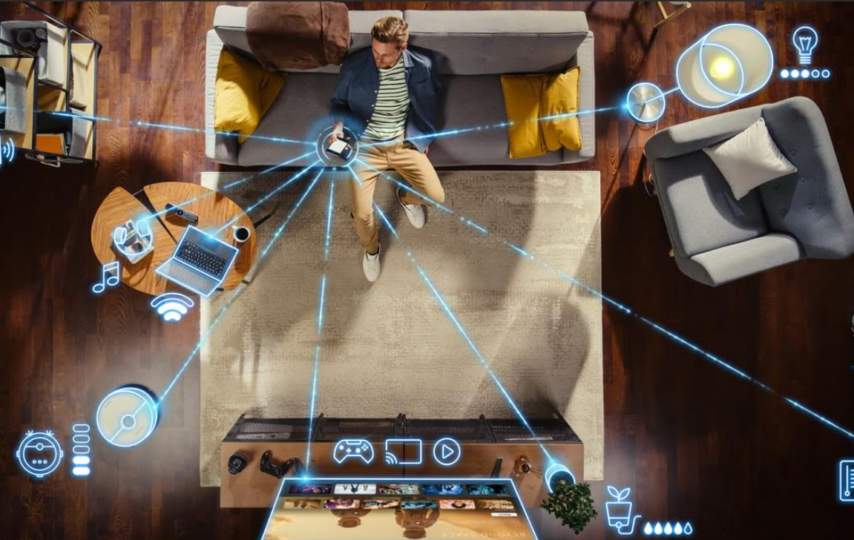

In the modern business landscape, maintaining robust connectivity across devices and equipment provides invaluable visibility into real-time performance. As legacy machinery integrates expanded telemetry and control capabilities through Internet of Things (IoT) upgrades, it drives previously impossible visibility and responsiveness gains.

The Advantages of Connectivity

For decades, most equipment operated as closed systems, offering minimal insights into ongoing function without direct observation. The rise of affordable sensors and wireless networking has shattered these information barriers through IoT integration. The key benefits include:

- Real-Time Status Updates: IoT sensors can monitor metrics like temperature, vibration, and energy usage, then relay readings in real-time. This enables constant equipment health checks remotely without requiring physical inspections.

- Early Failure Prediction: Connected devices transmit extensive performance data for advanced pattern analysis. Machine learning algorithms running in the cloud can detect the subtle early changes preceding equipment failures days or weeks in advance.

- Accelerated Maintenance: Mechanics no longer need to wait for broken equipment before deploying urgent repairs. IoT status readings allow precise planning maintenance around optimized windows instead of reactive calls. The result is less downtime and costs.

- Informed Updates: Operational analytics of IoT data determines ideal hardware and software tweaks for maximizing output. Connectivity enables deploying upgrades remotely without costly change management projects.

The collective impact across an entire organization is less asset downtime through predictive maintenance, lower repair expenses from prevention over reaction, improved output via continual optimization and leaner operations not requiring as much hands-on intervention thanks to connectivity.

The Optimal Pathway Forward

The most effective IoT adoption strategy begins with identifying one high-priority operational challenge, such as recurring failures in key generators. This focuses efforts on small sensor deployment pilots meant to solve a major efficiency issue. According to the experts at Blues.com, wireless IoT devices retrofit onto legacy equipment relatively easily provide status updates to the cloud for automated pattern analysis. The prevented generator failures and repaired efficiency metrics make the value rapidly clear.

Sustained small-scale successes secure greater leadership support and funding for incremental expansion across further equipment categories. While overall connectivity efforts ramp up over 12-24 months, each deployment stage focuses on addressing another urgent operational bottleneck, like production line downtime, inventory loss rates or equipment calibration deficiencies. This targeted pathway forward prevents overextending resources before proving device connectivity value in each phase while covering entire operations.

Eventually, expanded analytics uncover efficiency opportunities spanning across multiple equipment categories by correlating their collective performance data flows. This builds a system-level view that lets automation and artificial intelligence optimize everything in unison rather than through isolated efforts. Maximum optimization gets achieved through connections.

The Efficiency Multiplier Effect

As legacy equipment upgrades into the modern connectivity era through embedded sensors, built-in processing and wireless networking, they transform from passive machinery into active contributors toward enterprise optimization. Previously siloed efficiency efforts converge across departments as equipment essentially collaborates through perpetual data sharing. Combined with the expanding power of cloud analytics, even small optimizations compound daily into immense efficiency gains over months and years. The collective impact far outweighs the sum of isolated optimization efforts.

Conclusion

The machine age operated equipment as isolated assets with minimal transparent into health and performance without direct physical oversight. Advancements in sensor technologies, embedded computing and wireless networking have shattered these information silos for good through expansive IoT integration.

Efficiency efforts will converge across entire organizations as equipment collaborate through shared operational data. Connectivity introduces a digital multiplier effect on process improvements that accelerates exponentially over time. The data access barriers of the past can no longer restrain efficiency gains as the world enters a new era of interconnected optimization.