In June 2003, held in the U.S. city of Chicago, the retail industry systems exhibition (Retail Systems Conference & Systems), Wal-Mart announced that it would adopt a technology called RFID to eventually replace the current widespread use of bar codes, becoming the first company to announce the official adoption of the technology schedule. According to the plan, the company’s 100 largest suppliers should begin in January 2005 to supply goods in boxes (trays) on the RFID tags, and gradually expand to individual items. If the suppliers do not meet this requirement in 2008, they may lose the qualification for Wal-Mart supplies.

Metro in Germany Rheinberg (Rerhberg) opened the “future of the store” in late April officially opened for business, the cornerstone of the store is RFID technology. Now, Wal-Mart has quickly followed suit and announced even more radical and bold plans. A stone stirred a thousand waves, RFID technology has suddenly come into the spotlight. So, what is RFID technology, and what benefits can Wal-Mart get from it?

An Alternative to Bar Codes

People familiar with bar codes (Universal Product Code, UPC) know that the technology matured more than 30 years ago, but only a few companies are willing to adopt it. few companies were willing to adopt it until 1984, when major retailers such as Wal-Mart mandated that their suppliers adopt the Wal mart rfid. The number of companies printing bar codes on merchandise increased rapidly from less than 15,000 in 1984 to more than 75,000 in 1987. to more than 75,000 in 1987. The popularity of bar codes greatly improved the efficiency of goods handling and created new profit growth for retail businesses. The popularity of bar codes has greatly improved the efficiency of goods handling and created a new profit growth point for retailers.

Although the bar code has made a great contribution to improving the efficiency of goods distribution, it has some insurmountable defects. For example, the scanner must “see” the barcode in order to read it, so staff must scan each item by hand – not only less efficient, but also prone to errors. and prone to errors. In addition, if a bar code is torn, smeared or lost, the scanner will not be able to scan and identify the item. For example, barcodes have limited information capacity and usually only record the manufacturer and product category.

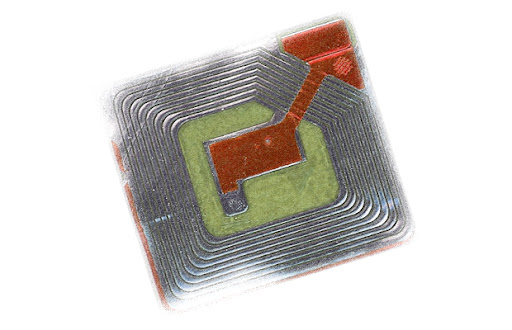

RFID, which is thought to replace bar codes, is a contactless automatic identification technology called “(radio) frequency identification”, named after its English name “Radio Frequency Identification”. It is named after the acronym “Radio Frequency Identification”. A simple RFID system consists of a Tag, a Reader and an Antenna. A simple RFID system consists of a Tag, a Reader, and an Antenna – and in practice requires additional hardware and software support. Each RFID tag contains a UPC-like and called the “Electronic Product Code” (EPC) identification code, using radio communication The data in the tag is read by a reader and then processed by the system database or other application software, as well as the realization of the tag is read by a reader and then processed by the system database or other application software, as well as the tracking of goods and other functions.

Wireless data communication method and “anti-collision” algorithm (Anti-collision Algorithm) and other features, so that RFID can be scanned at a certain distance from the product, in the case of the RFID tag, the tag can be scanned at a certain distance. The RFID can scan the product from a certain distance and accurately identify the specification and quantity of the product inside the box without opening the package. Therefore, it is only necessary to push the goods from the effective reading distance of the reader, you can achieve the identification of each piece of goods, no longer need to unpack the whole box of goods, and then scan the bar code piece by piece, and the bar code can be scanned. Open, and then piece by piece scanning bar code, thus greatly improving the efficiency and accuracy of the processing of goods. Furthermore, the data capacity of RFID tags is relatively Large data capacity, you can identify the goods as A company in B time, C location of the production of D goods of the E piece, rather than the bar code usually identified by Company A’s Class B goods. In addition, because of the RFID closed packaging method, it can be used in wet, dusty and other serious pollution environment. However, RFID is not new.

However, RFID is not new. Its history dates back to World War II, when the U.S. Army first used it to identify Allied aircraft. By the 1970s, the then West German government was using it to identify nuclear waste to more accurately track their disposal process. In Singapore and Hong Kong, electronic road pricing systems based on this technology have been in use for a long time, and the system can be applied to vehicles traveling on different roads at different times. In Singapore and Hong Kong, the electronic highway toll system based on this technology has been in use for a long time, the system can travel in different sections of vehicles at different times to implement differential billing. In addition, it is also in the pet identity recognition, wildlife and environmental monitoring and other fields. In addition, it has also been applied in the fields of pet identification, wildlife and environmental monitoring.

Some readers may ask, since this technology has been around for so long and has so many advantages over bar codes, why is it the bar code that has gained popularity? Why is it that bar codes have gained popularity, while the development of RFID has been stagnant? And after a number of years of silence, and why has it suddenly emerged?

RFID advantage and disadvantage

The promotion and popularity of a technology, both with the prevailing social needs and application environment, and ultimately depends on its effectiveness on the adopters The reason why RFID has not been well developed for a long time, there are unique historical reasons, and In recent years, it has regained its strength thanks to the maturity of the application environment and the birth of several new technologies. For a long time, price has been the primary factor limiting the development of RFID. After decades of development, the price of RFID tags remains High – passive tags and active tags are priced at 30 cents and more than $ 1. This is a major problem for more expensive items, such as for more expensive items such as automobiles and high-end clothing; however, if they are used for relatively low-cost fast-moving consumer goods (FMCG), the price of RFID tags is still high. (FMCG), consumers are afraid that they will have to “buy the box and return the pearl”. In addition, the price of RFID readers are mostly more than $ 1,000, and an enterprise will often need to install dozens, or even thousands of similar machines. If you add computers, local area networks, application software, the system integration costs, the majority of small and medium-sized enterprises can undoubtedly only be discouraged. Fortunately, new manufacturing technologies are expected to significantly reduce the price of RFID tags in the near future. Already for Gillette (Gillette) to provide 500 million tags of Allen (Alien Technology Corp.) said its invention of “fluid self-assembly” (Fluidic Selfassembly) new process can greatly reduce manufacturing costs, if the order quantity of 10 billion or more, the price can be as low as 5 U.S.cents if orders reach 10 billion pieces or more. Israel’s SmartCode claims to have a production capacity of 1.2 million pieces per hour and that prices can be controlled if orders reach 1 billion pieces or more. If the order quantity reaches more than 1 billion pieces, the price can be controlled between 5-10 cents. According to technical expert analysis, after the unit price of passive tags drops to 10 cents can be applied on a large scale to the whole box of whole goods; down to less than 3 cents, it is possible to popularize to a single piece of packaged consumer goods. And because Texas Instruments (TI) and other companies’ unremitting efforts, the price of other hardware devices such as readers will also drop significantly.

Secondly, the immature application technology environment is another important reason why RFID has only received attention so far. Not only the need for hardware (tags and readers, etc.) manufacturing, wireless data communications and networks, data encryption, automatic data collection and data mining, etc. technology, but also must be integrated with the enterprise resource planning (ERP) and warehouse management system (WMS), otherwise it is difficult to fully realize the benefits of this The benefits of this technology – which is a great challenge for system integration.

Today, the development of wireless data communication, data processing and networking technologies have become increasingly mature, and in IT technology giants such as SAP and IBM directly driven by IT giants such as SAP and IBM, the supporting technologies have reached the level of practical application and are already being used in Metro’s “Store of the Future” in Rheinberg, Germany. The “store of the future” opened by Metro in Rheinberg, Germany, has been tested in practice. In addition, Microsoft, which is keen and good at capturing market opportunities, recently announced that it will fully develop and RFID technology-compatible applications.

Once again, the lack of unified technical standards to restrict RFID breakthroughs in the confines of corporate boundaries. For a long time, most of the companies using are proprietary (proprietary) technology, the frequency used, coding, storage rules, as well as data content are not the same. Readers and tags cannot be common, between enterprises and enterprises cannot be smooth data exchange and collaborative work, thus the application of RFID technology The scope is limited to the internal of a certain enterprise.

The efforts of the MIT Auto-ID Center are expected to successfully address the problem of incompatible national technology standards. The center was established in 1999, members also include the United Kingdom, Sweden and Japan and other countries of the five universities, and more than 100 leading companies in various industries, such as Procter & Gamble, Coca-Cola, Kodak, IBM (consulting), Mitsui, Intel and British Telecom and other companies to sponsor its research funds. The Center is a non-profit technology consortium with a mission to create the “Internet of Things” (Internet of Things). To this end, the center will work with many member companies to develop a unified, open technology standard similar to the Internet, based on the existing computer Internet, to achieve the exchange and sharing of commodity information. In addition, under the leadership of the Japanese government’s Ministry of Economy, Trade and Industry, dozens of Japanese companies have joined together to establish the Ubiquitous ID Center, which is similar to the Auto-ID Center, and will propose their own technical standards.

In addition, for the protection of customer privacy, tag data encryption and other issues that once hindered the application of RFID, there have been companies have proposed corresponding solutions. It can be said that the application of RFID technology environment has become increasingly mature, large-scale practical applications also have a realistic basis.

RFID: to create a “transparent” supply chain of tools

Enterprises using a technology, the main purpose is no more than two: to obtain rich short-term profits, consolidate or seek long-term competitive advantage. To examine Wal-Mart’s intention to adopt RFID technology, first of all, we must also talk about its competitive advantage or core competencies.

Since its founding in 1962, Wal-Mart has grown at a mind-boggling pace. To date, the company has opened more than 4,300 stores worldwide, and after topping the Fortune 500 with $219.8 billion in sales in 2001, it topped the list again in 2002 with $246.5 billion. Over the past five years, its sales have soared an average of 15.7 percent annually. According to Fortune’s forecast. Wal-Mart will also maintain its leading position for the next few years and reach $434 billion in sales in 2007.

Wal-Mart’s success lies in its clever combination of cutting-edge technology and superior service. More specifically, an efficient supply chain and logistics management system is its core competitive ability. David Glass, former CEO of Wal-Mart, once said it all If there’s one thing we do better than anyone else, it’s a distribution center. If there’s one thing we do better than anyone else, it’s distribution centers.” The supply chain and logistics management system created by making full use of modern information technology has not only gained cost advantages for Wal-Mart, but also deepened its understanding of customer demand information. It has gained a valuable competitive advantage by deepening its understanding of customer demand information and increasing its speed of market response.

Wal-Mart has always played the role of a technology pioneer, always seeking competitive advantage by adopting various new technologies. As early as 1969, the company began using computers to manage inventory; in ’80 it began using bar codes; in ’83 it spent another $24 million on commercial satellites to In ’83, the company spent $24 million on commercial satellites to build a global communications network; in ’85, it began building a massive electronic data interchange (EDI), which evolved into the multi-functional Retail Link system with multiple functions; wireless laser scan gun in ’88; and in the 1990s, the fleet was equipped with a satellite positioning system to improve By the 1990s, the fleet was equipped with a satellite positioning system to improve the efficiency of logistics management. Wal-Mart’s technology is often 5 to 10 years ahead of its peers in the same stores. We can see that all of Wal-Mart’s technology is invariably centered on improving supply chain and logistics management as a core competitive capability.

By now, 85% of the work in Wal-Mart’s distribution centers is done automatically by machinery, and of the more than 80,000 kinds of goods sold in its local stores 85% of the more than 80,000 products sold in its local stores are centrally distributed. Using laser scanners and computer networks, Wal-Mart can track merchandise from inventory, distribution, delivery, shelving and sale. This allows Wal-Mart to track the entire process from stocking, distribution, delivery, shelving and selling, thus synchronizing store sales with distribution and aligning distribution centers with supplier operations. The company can even allegedly complete an inventory of all merchandise in more than 4,300 stores worldwide within one hour. All this is based on the barcoding of merchandise information. All of this is based on the barcoding of product information.